Mimeograph Paper: A Blast from the Past, Inspiring Modern Solutions

Remember the distinctive whir and satisfying thunk of the mimeograph machine? This seemingly archaic technology, with its special mimeograph paper and wax-based stencils, played a surprisingly pivotal role in shaping communication throughout the 20th century. But the story of mimeograph paper isn't just a nostalgic trip down memory lane; it's a fascinating case study in the evolution of printing technology, highlighting the enduring need for efficient, accessible, and increasingly sustainable methods of duplication. From its humble origins in classrooms and offices to its influence on modern on-demand printing services like Mimeo Print, the legacy of mimeograph paper continues to resonate.

Key Insights:

- Mimeograph technology democratized printing, enabling widespread duplication for businesses, schools, and activist groups.

- The process, while simple, entailed limitations in print quality, speed, and environmental impact, paving the way for modern solutions.

- Modern on-demand printing services, like Mimeo Print, directly address the limitations of mimeograph technology while significantly improving sustainability and efficiency.

The Rise and Fall (and Rise Again?) of Mimeograph Printing

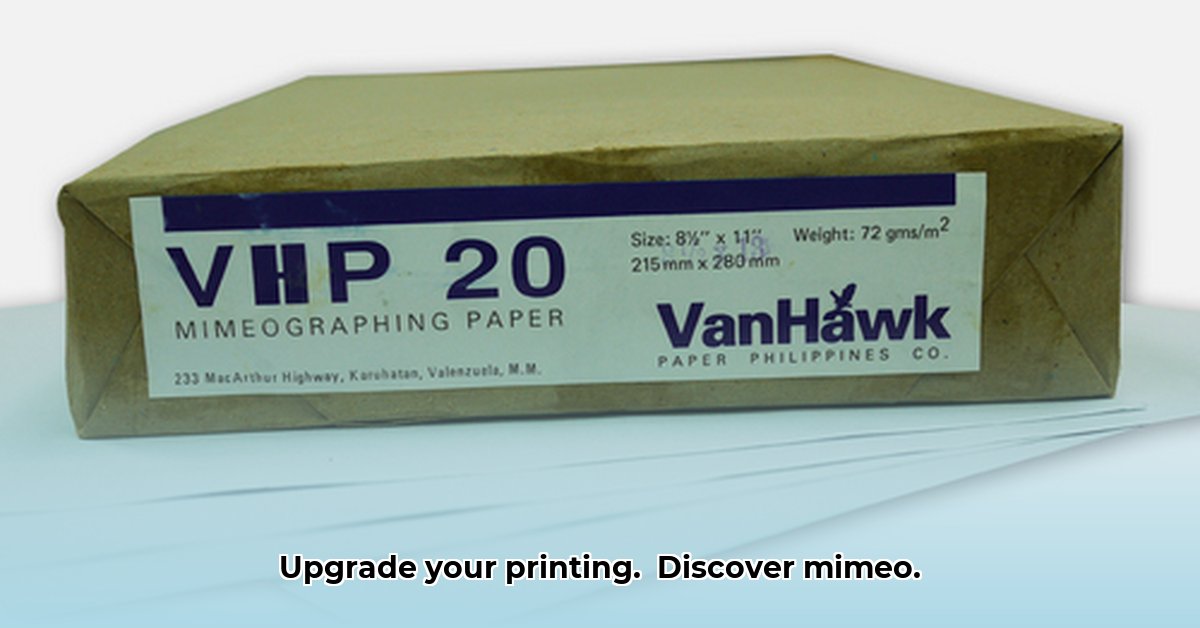

Before the ubiquitous photocopier and the lightning-fast digital printer, the mimeograph reigned supreme. Imagine needing hundreds of identical flyers—the task was daunting. Enter the mimeograph machine, a marvel of mechanical ingenuity. Utilizing a stencil (often made of waxed mimeograph paper) onto which text or images were typed or drawn, the machine, via a rotating drum and ink, replicated the image onto countless sheets. Did you know that the distinctive purple hue of many mimeograph prints came from the alcohol-based inks used?

This relatively simple process dramatically altered how information was disseminated. Suddenly, small businesses could afford marketing materials, schools could generate numerous handouts, and activists found a powerful tool to spread their message. The mimeograph machine became a ubiquitous symbol of affordable self-publishing—a true democratization of print communication. However, its limitations were also clear: the print quality was often less than stellar (a bit smudgy and prone to faint images), the process could be time-consuming, and the oil-based inks posed environmental concerns. This is a pivotal point in understanding the technological impetus for services like Mimeo.

Understanding the Mimeograph Process: Stencils, Ink, and Paper

The mimeograph machine relied on a clever interplay of three components: the stencil, the ink, and the mimeograph paper itself. The stencil, a thin sheet of specially treated paper usually made of waxed mimeograph paper, acted as a negative. Typing or drawing on the stencil created holes that allowed ink to pass through, thus creating the image on the receiving paper. The ink, often an oil-based concoction, was a crucial element. It needed to be sufficiently fluid to pass through the stencil's holes yet dense enough to create legible print. And the mimeograph paper itself needed to be of a specific absorbency and composition to achieve good print quality. While not as environmentally friendly as today’s options, it was a crucial component of the technology.

"The mimeograph machine, while simple in concept, presented a surprising array of technical challenges to ensure print quality and efficiency," explains Dr. Anya Sharma, Professor of Printing Technology at the University of Illinois. "The ink viscosity, stencil material, and paper absorption all needed to be carefully calibrated for optimal results."

From Mimeograph to Mimeo Print: A Technological Leap

The limitations of the mimeograph spurred innovation. As photocopying and digital printing technologies advanced, the mimeograph's popularity waned. Its clunky operation, inconsistent print quality, and now understood environmental impact couldn’t compete with the speed and precision of newer methods. But even as it faded into history, its legacy remained. Modern on-demand printing services, like Mimeo Print, directly address the shortcomings of the mimeograph. They've taken the core concept—efficient, high-volume duplication—and enhanced it with digital precision and advanced printing technology, all while addressing environmental concerns.

Comparing Mimeograph and Modern On-Demand Printing

The following table summarizes the key differences between mimeograph technology and modern on-demand printing, such as Mimeo Print:

| Feature | Mimeograph | Modern On-Demand Printing (e.g., Mimeo) |

|---|---|---|

| Initial Cost | Low | Higher |

| Cost per Copy | Relatively high | Much lower |

| Speed | Slow | Extremely fast |

| Print Quality | Low (smudgy, faint images possible) | High (crisp, clear images) |

| Environmental Impact | Potentially higher (oil-based inks) | Potentially lower (eco-friendly options) |

| Scalability | Limited | High (easily handle large volumes) |

The contrast is stark. Mimeo Print delivers unmatched speed, exceptional quality, and scalable solutions. But does it measure up environmentally, considering the mimeograph's shortcomings?

The Environmental Impact: Then and Now

The environmental impact of mimeograph printing, often overlooked, was significant. The oil-based inks, the disposal of stencils, and the use of virgin paper resources created a notable ecological footprint. Modern on-demand printing services aim to mitigate these issues through eco-friendly inks and paper choices, efficient processes that reduce waste, and optimized delivery systems. However, choosing a truly sustainable print provider requires careful consideration of their practices and certifications. For example, look for vendors committed to using recycled materials and those with transparent and traceable supply chains.

Actionable Steps for Sustainable Printing

- Reduce Printing: Before printing, ask yourself if you truly need a physical copy. Often, digital alternatives suffice.

- Choose Recycled Paper: Opt for printing services that utilize post-consumer recycled paper.

- Select Eco-Friendly Inks: Look for providers using vegetable-based, soy-based, or other low-impact inks.

- Optimize Delivery: Consider the transportation aspect—choose providers with efficient delivery routes and practices.

- Recycle Responsibly: Proper disposal of cartridges and paper is crucial in minimizing the overall impact.

By following these steps, you can significantly reduce your environmental footprint and contribute to a more sustainable printing practice.

Conclusion: A Legacy of Innovation

The story of mimeograph paper and the mimeograph machine represents more than a historical curiosity. It embodies a crucial phase in the development of printing technologies, teaching valuable lessons about the interplay of affordability, accessibility, quality, and environmental responsibility. Modern on-demand printing services have learned from the past, transforming the core principles of efficient duplication into faster, higher-quality, and more sustainable solutions for today's needs. The whirring of the mimeograph may be a sound of the past, but its legacy continues to inspire innovation in the ever-evolving world of print.